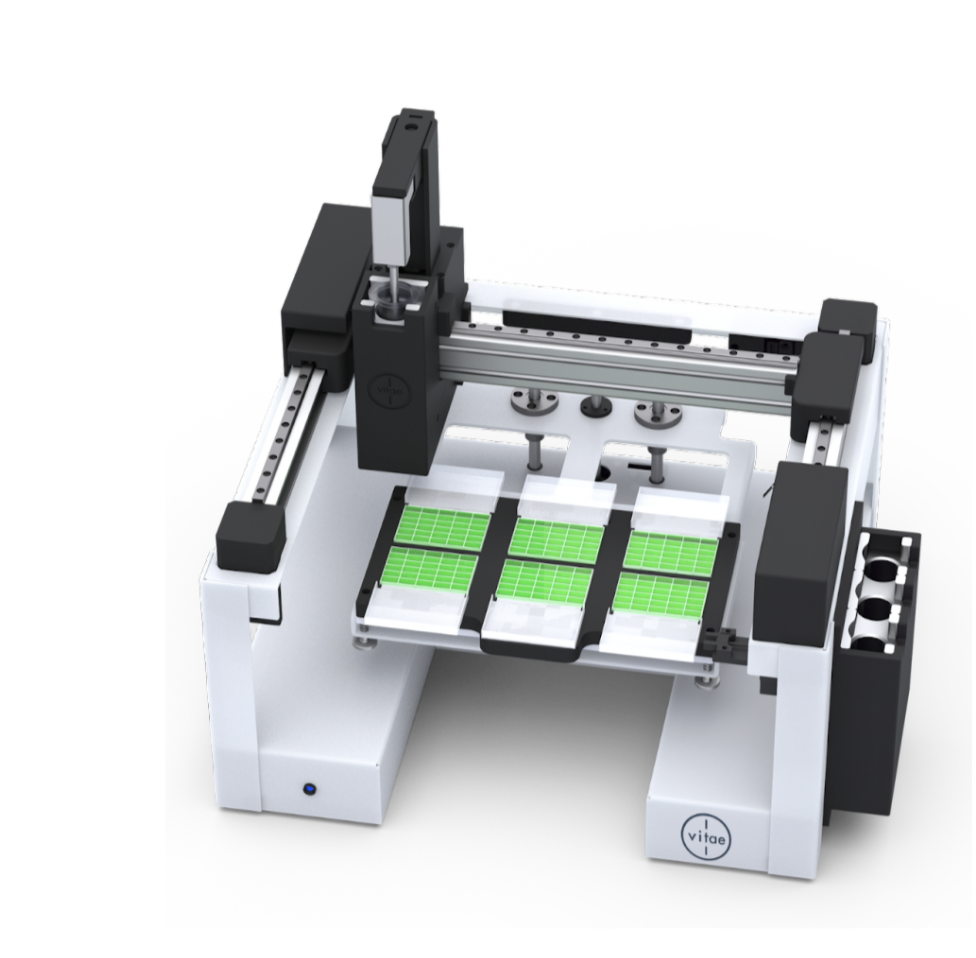

In the Summer of 2021 I worked with Vitae Industries to redesign parts on their Pharmaceutical Autocompounder with the goal of reducing costs and increasing durability

Challenges included:

- Learning constraints and functions of different parts.

- Communicating with manufacturers to make sure parts could be fabricated.

- Working with the head engineer to understand design challenges.

I would redesign a part, make contact with a manufacturer to get a quote, and then iterate the design base on their feedback. was able to find cheaper, more sustainable manufacturing options for a critical part on their main product. I gained experience in SolidWorks and learned about different manufacturing processes and their constraints.

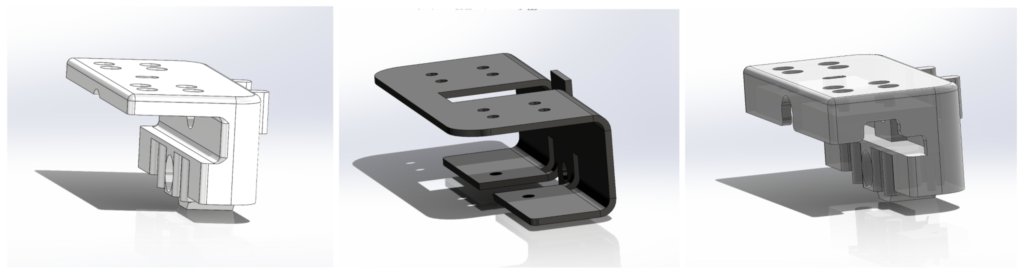

Below is an example of a part I redesigned for three different manufacturing processes: